Using XR to preserve expertise, accelerate onboarding, and bridge skills gaps as the manufacturing workforce evolves

By Gilad Tzori, COO at frontline.io, summary excerpt from article originally published on Design News

As industries face a growing skills gap, transferring decades of expertise to new technicians has never been more urgent. Manufacturers today are facing a global knowledge transfer challenge: senior experts are retiring while new digital-native employees enter the workforce expecting on-demand learning and interactive tools. XR training and digital twins present a modern approach to scaling expertise and accelerating onboarding, without relying solely on traditional in-person instruction.

In this Design News article, Gilad Tzori explores how XR training and digital twins preserve institutional knowledge, accelerate onboarding, and enable scalable workforce development in manufacturing. By capturing expert workflows in immersive formats, companies ensure critical operational know-how is not lost, but accessible anywhere, anytime.XR training can bridge the intergenerational divide in modern manufacturing.

(Topics: XR training, digital twins, manufacturing workforce, onboarding, knowledge transfer)

At a Glance – Why XR matters now

- Institutional knowledge loss is accelerating as experts retire

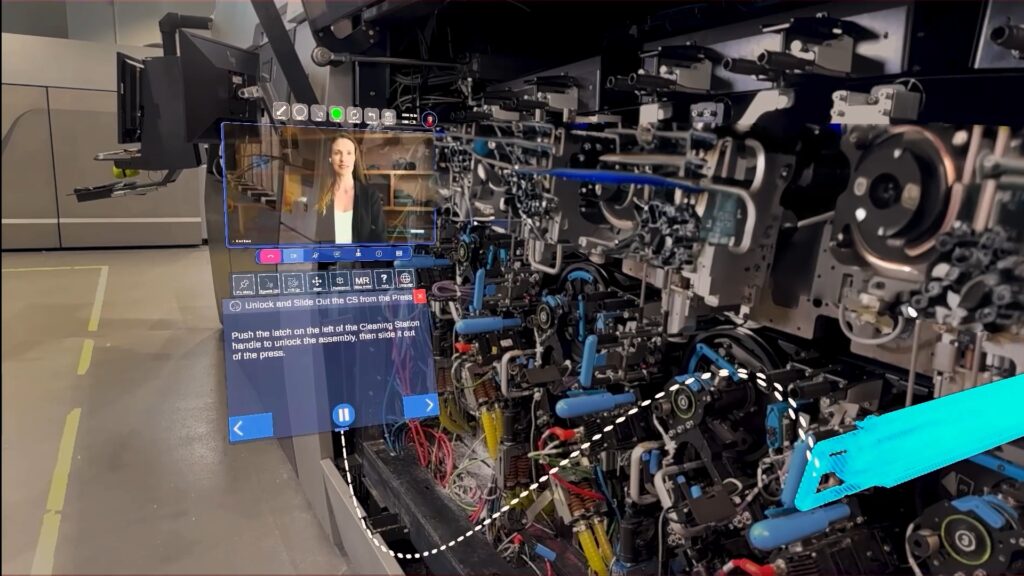

- New technicians expect digital, hands-on learning

- Traditional training is slow and inconsistent to scale

- XR offers real-world simulation for faster skills acquisition

The pitfalls of outdated training methods

In an industry already strained by a talent shortage, relying on outdated training methods to onboard new workers only compounds the problem. Traditional training methods like manuals, classroom sessions, and static video tutorials are getting more ineffective by the day. The current generation of workers, particularly those just entering the industry, has grown up in a digital-first world. They expect training experiences that are interactive, dynamic, and immersive.

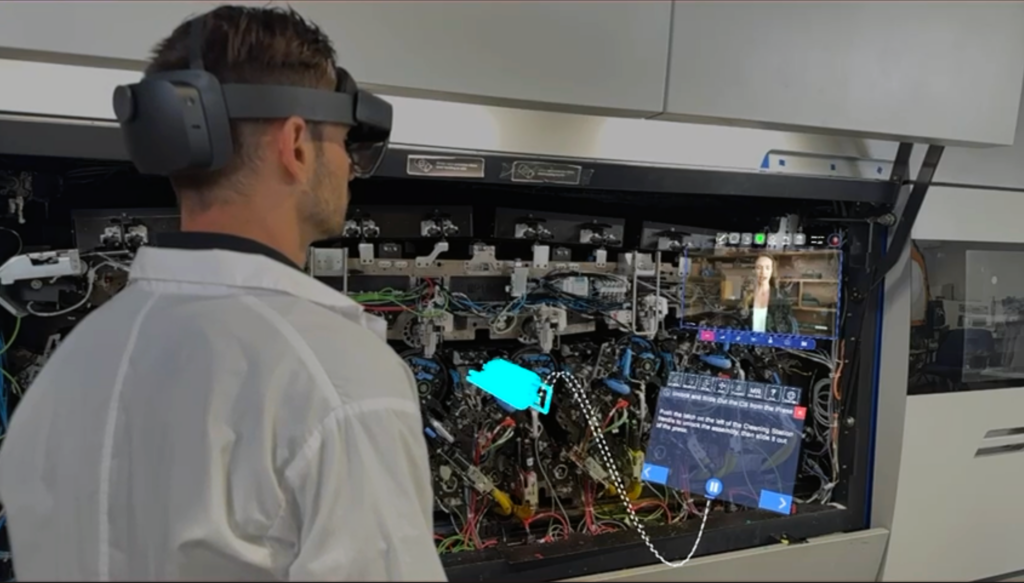

frontline.io perspective — Bringing XR training into reality

While the Design News article highlights the industry challenge, we see the impact firsthand. With frontline.io, manufacturers can turn expert knowledge into digital twin workflows, XR training modules, and guided step-by-step procedures available across: Mobile & tablet, PC & browser and AR/VR headsets. This means teams can train in real-time simulations, remotely, and at scale, without needing an expert present on the factory floor.

With frontline.io, companies:

- Accelerate onboarding and reduce training time

- Preserve knowledge from retiring experts

- Reduce human error and machine downtime

- Standardize processes across all sites

- Train globally with the same high-quality experience

Want to explore XR training for your team? Book a demo